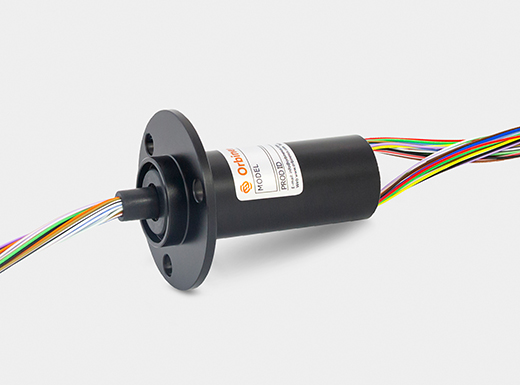

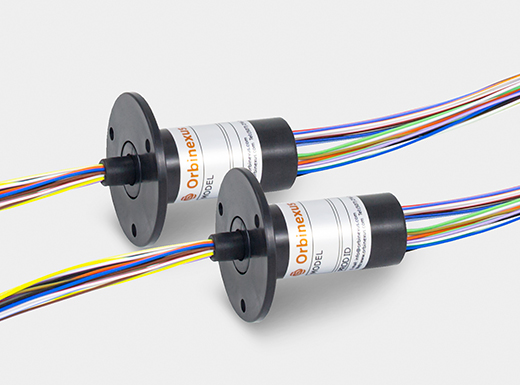

Slip Ring Connector

Slip ring connector is the second name for a slip ring which is the main type of a slip ring. Slip ring connector connects a stationary and a rotatory part of a device while providing continuous transmission of power and/or data and it has a very versatile use.

Slip Ring Motor

Slip rings are also used in induction motors as speed controllers so you can often find them in devices where gradual build-up of power is required.

Their purpose is often found in machines and devices such as plunger pumps, cranes, elevators, and more.

Rotary Slip Ring

Rotary slip rings are built in a different way and are built more like a rotating union.

This rotating union helps meet the most demanding needs in the industry for devices that include an extensive range of rotating units.

Rotary slip rings can also support liquids and gasses, besides transmitting power and signal.

Slip Ring Generator

Slip ring generator is a type of slip ring which is used in AC generators. Their design is hollow where the end of the rings connects with the armature coil>

Upon rotation, slip ring generators help generate and produce AC current.

Slip Ring Assembly

Slip ring assembly is a type of a slip ring that’s used to connect sensors to rotating equipment and devices.

These types of slip rings can also transmit ethernet signals to provide readings of these sensors virtually.

Slip Ring Commutator

Slip ring commutator is a specialized version of a slip ring for use in DC motors where its main purpose is to transfer power between stationary housing and a rotating armature.

This type of slip ring can also reverse the direction of the electrical current.

Pay Online

Pay Online Get A

Quote

Get A

Quote